The Bolt is a collective of roofing contractors trained in best practices for directing water away from your home. As certified contractors, we ensure your home withstands nature’s toughest storms and offer peace of mind with a reliable warranty.

Now You're Backed

by The Bolt

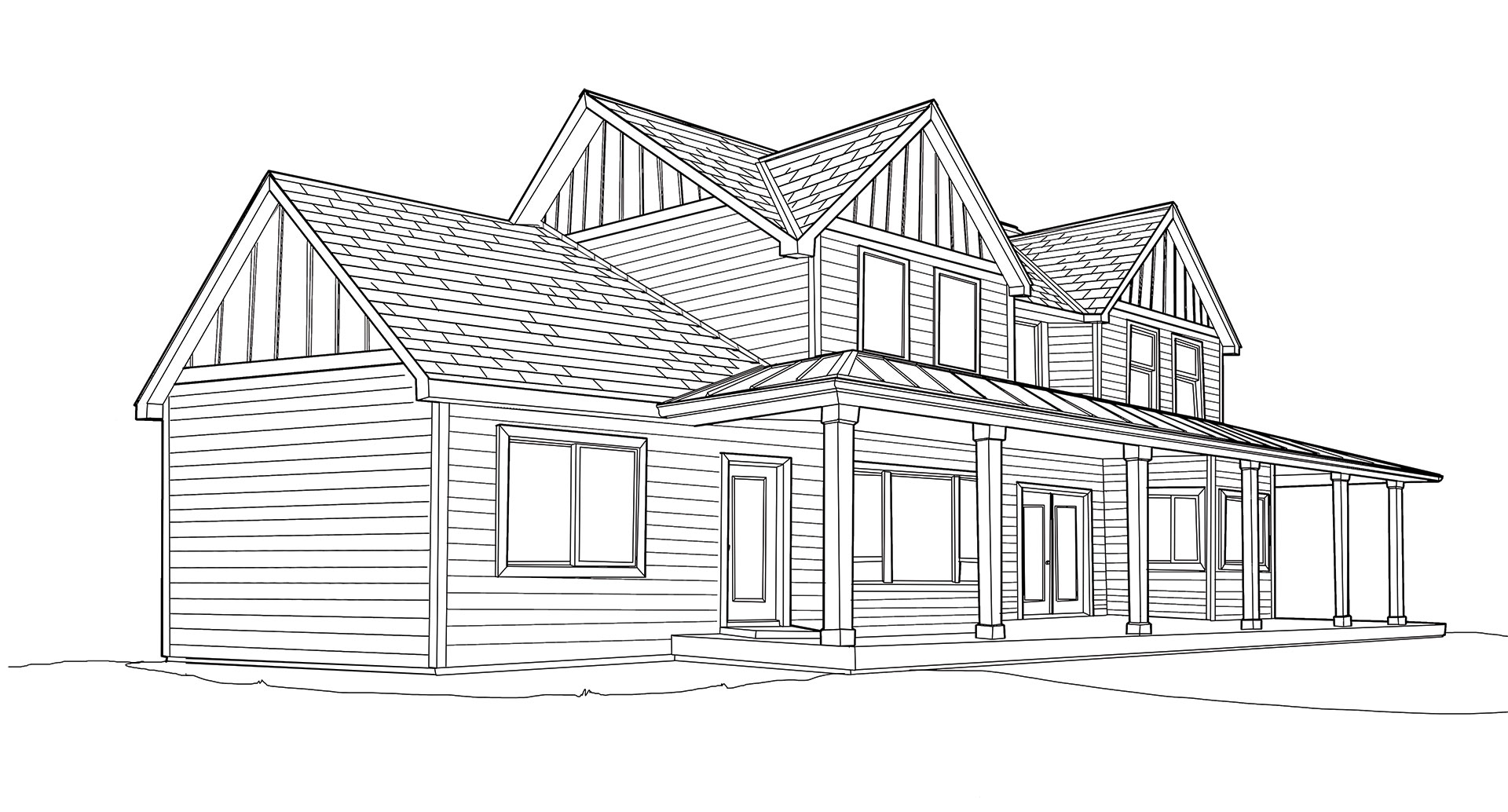

Your Home Has Over 300 Fail-Points

Valleys, seams, gaps, roof-to-wall junctions, and penetrations like vents and windows

We’ve identified

roof flashing best practices...

Based on International Building Codes

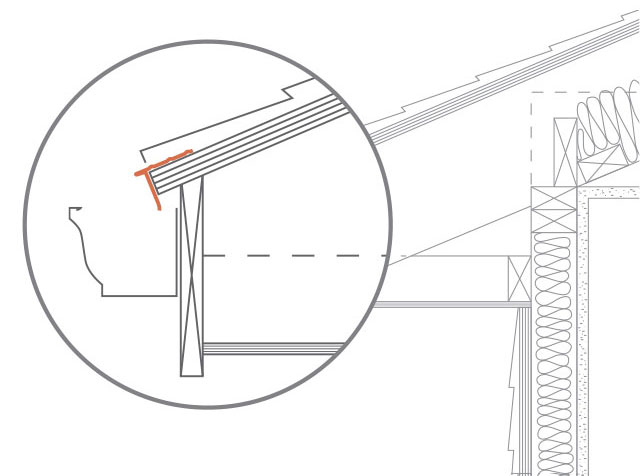

Infinity Drip Edge

Water Prevention

Drip Edge is essential in directing rainwater away from your roof and fascia to protect your home from moisture damage.

A drip edge shall be provided at eaves and gables of shingle roofs. Adjacent pieces of drip edge shall be overlapped a minimum of 2 inches (51 mm). Source: IRC 2018 Code: R905.2.8.5

Drip edges shall extend a minimum of 0.25 inch (6.4 mm) below the roof sheathing and extend up the roof deck a minimum of 2 inches (51 mm). Drip edges shall be mechanically fastened to the roof deck at a maximum of 12 inches (305 mm) o.c. with fasteners as specifi ed in Section R905.2.5. Underlayment shall be installed over the drip edge along eaves and under the underlayment on gables. Unless specifi ed diff erently by the shingle manufacturer, shingles are permitted to be fl ush with the drip edge.

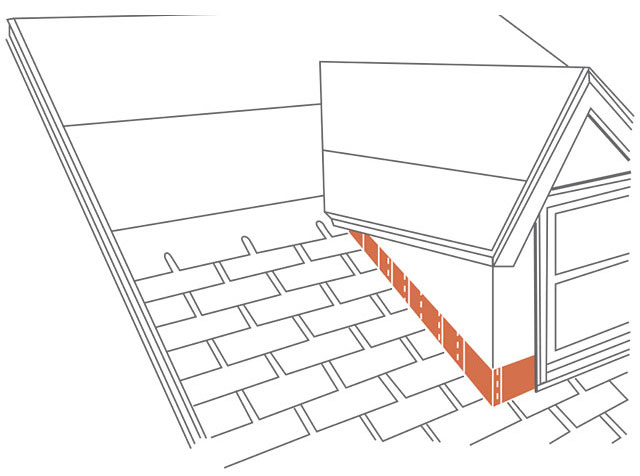

Step Flashings

Water Prevention

Drip Edge is essential in directing rainwater away from your roof and fascia to protect your home from moisture damage.

Flashings shall be applied according to the asphalt shingle manufacturer’s printed instructions.

Base flashing shall be of either corrosion-resistant metal of minimum nominal 0.019-inch (0.5 mm) thickness or mineral surface roll roofing weighing a minimum of 77 pounds per 100 square feet (4 kg/m2). Cap flashing shall be corrosionresistant metal of minimum nominal 0.019-inch (0.5 mm) thickness. Source: IRC 2018 Code: R905.2.8.1,3,4

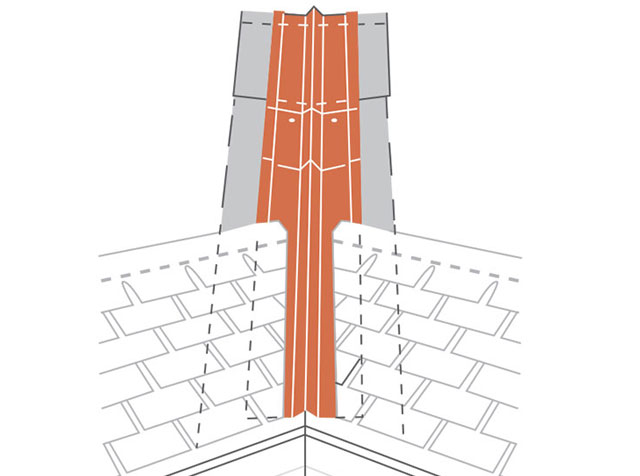

W-Valley

Flare Out Prevention

Our Pre-Notched and Infinity Drip Edge’s create a continuous, smooth edge that maintains proper alignment and ensures a flat face.

Valley linings shall be installed in accordance with the manufacturer’s installation instructions before applying shingles. Valley linings of the following types shall be permitted:

For open valleys (valley lining exposed) lined with metal, the valley lining shall be at least 24 inches (610 mm) wide and of any of the corrosion-resistant metals in Table R905.2.8.2. Source: IRC 2018 Code: R905.2.8.1

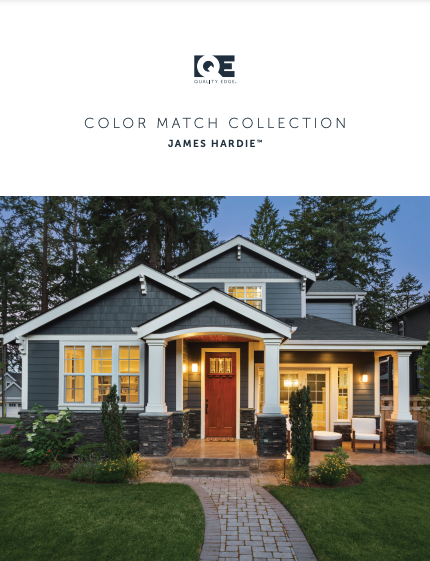

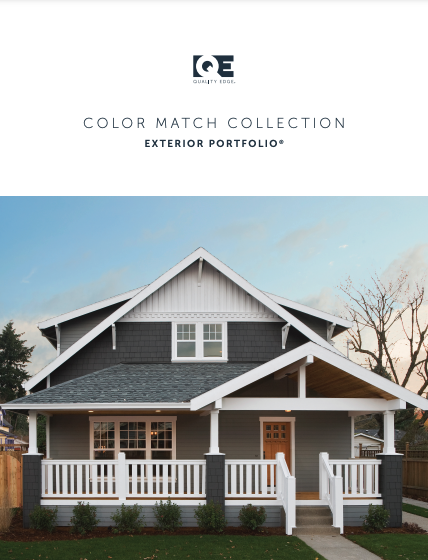

COLOR MATCH PROGRAM

The Integra Home Flashing System has matches to both shingle lines and to siding lines ensuring you get will make the right pick when you pick your flashings.

SHINGLE MATCH GUARANTEE

Matching the Shingle product duration to the flashings product duration of your shingle manufacturer, allows you to have peace of mind through every storm.