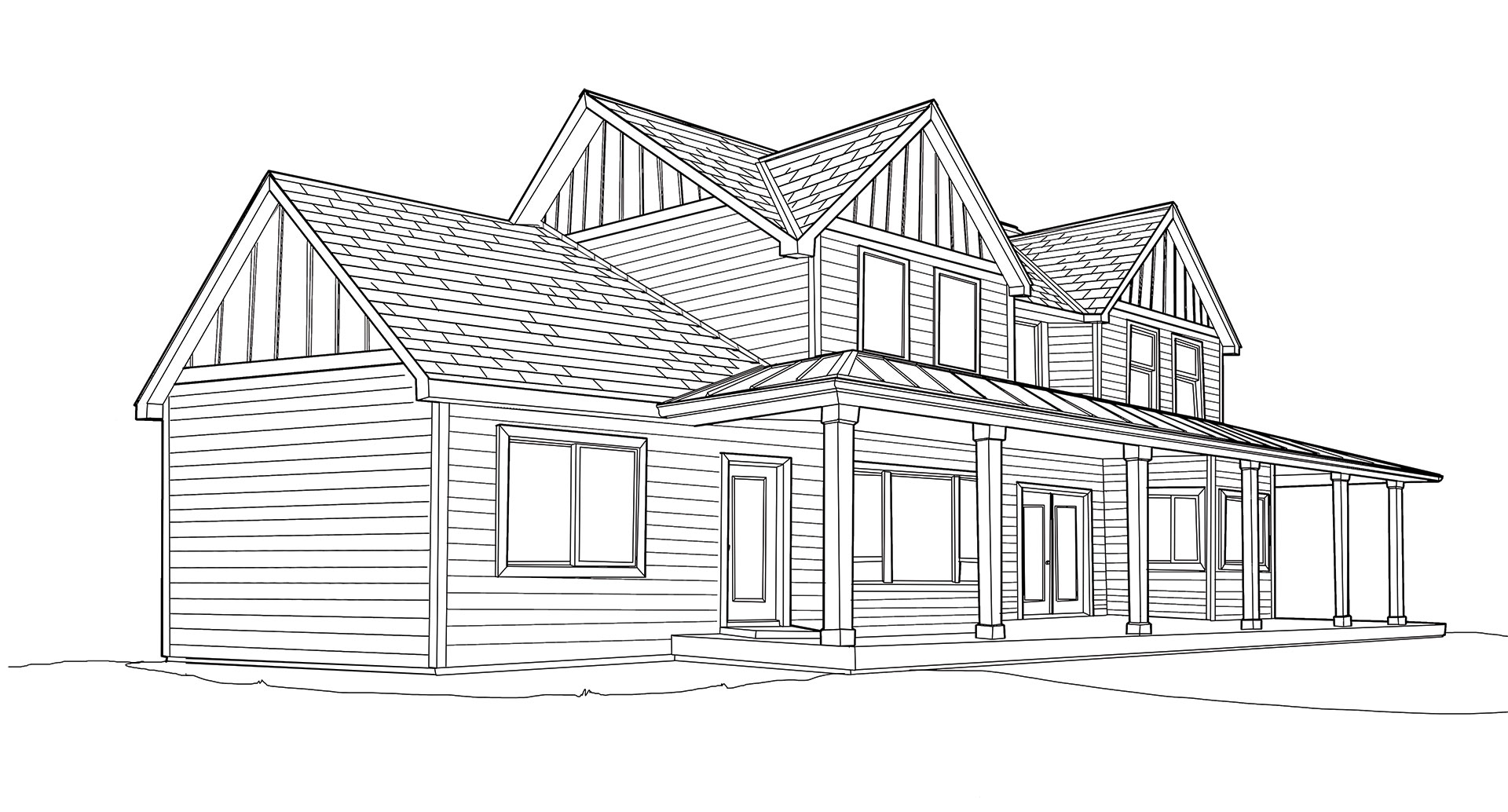

Water is the Enemy of Your Home

70

14

20

Our Mission

We ensure these weak

points do not fail.

With our expertise and Fail-Point Certification, we specialize in effectively managing these hazards away from your home, employing the highest standards and suitable materials to protect and enhance your roof.

We’ve identified

roof flashing best practices...

Based on International Building Codes

ROOF FLASHING

Drip Edge

A drip edge shall be provided at eaves and gables of shingle roofs. Adjacent pieces of drip edge shall be overlapped a minimum of 2 inches (51 mm).

Drip edges shall extend a minimum of 0.25 inch (6.4 mm) below the roof sheathing and extend up the roof deck a minimum of 2 inches (51 mm). Drip edges shall be mechanically fastened to the roof deck at a maximum of 12 inches (305 mm) o.c. with fasteners as specifi ed in Section R905.2.5. Underlayment shall be installed over the drip edge along eaves and under the underlayment on gables. Unless specifi ed diff erently by the shingle manufacturer, shingles are permitted to be fl ush with the drip edge.

Source: IRC 2018

Code: R905.2.8.5

ROOF FLASHING

Flashings

Flashings shall be applied according to the asphalt shingle manufacturer’s printed instructions.

Base flashing shall be of either corrosion-resistant metal of minimum nominal 0.019-inch (0.5 mm) thickness or mineral surface roll roofing weighing a minimum of 77 pounds per 100 square feet (4 kg/m2). Cap flashing shall be corrosionresistant metal of minimum nominal 0.019-inch (0.5 mm) thickness.

Source: IRC 2018

Code: R905.2.8.1,3,4

ROOF FLASHING

W-Valley

Valley linings shall be installed in accordance with the manufacturer’s installation instructions before applying shingles. Valley linings of the following types shall be permitted:

For open valleys (valley lining exposed) lined with metal, the valley lining shall be at least 24 inches (610 mm) wide and of any of the corrosion-resistant metals in Table R905.2.8.2.

Source: IRC 2018